Smooth power delivery, precise metering, and better mileage are just a few possibilities fuel injection brought to the biking world. The technology was first developed for cars under the constraints of emissions regulations and high fuel costs, but it would take considerably longer for motorcycle brands to catch on. Early injection systems were overly complicated, unpredictable, often inflicted with performance issues, and at most times, inferior to the carburettors they replaced.

It took motorcycle brands well over a decade to embrace and bring the tech to the standards we’ve come to expect today. Japanese manufacturers were the first to mass-market electronic fuel injection, first in their 1980s high-end bikes, and as the technology progressed, in their entire product lines. Iconic American brands like Harley-Davidson only started toying with fuel injection in the mid-1990s, around the same time that electronic fuel injection became standard in 1990s cars. The top-line Electra Glide Ultra Classic was the first hog to get it as an option. The Motor Company sold both carburetted and injected tourers and cruisers side by side until 2007, when the entire Harley range adopted the technology as the new normal.

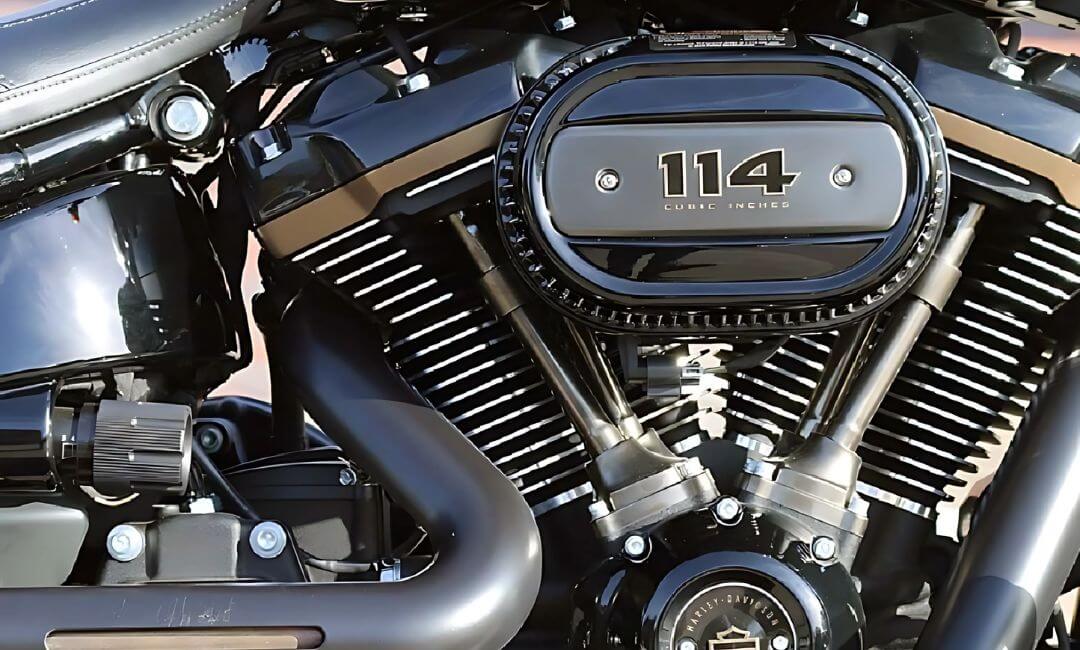

Besides meeting regulations, fuel injection in big V-twins brought linear power delivery, consistent performance in different riding conditions, and with related developments like a Harley Davidson fuel tuner, the ability to easily customize bikes with performance parts while maintaining warranties and engine longevity. This is an easy way to modify your V-twin’s stock settings, letting you fine-tune power, torque, air/fuel ratios and fuel use according to your needs.

Carburetted vs. Fuel Injected Engines

To understand the role of fuel tuners, first, let’s explain how carburettors and injection systems work to help the engine produce power. Both deal with how fuel and air are mixed and introduced into the cylinders before being ignited by spark plugs. The two technologies go about this in starkly different ways.

Carburettors are mechanical systems relying on air pressure and vacuum to get the correct air and fuel ratios for optimal combustion. They’re essentially large tubes situated vertically above the engine block, and connected to a horizontal fuel line. As air is drawn into the tube it speeds up due to the narrow opening known as the Venturi.

This creates a pressure drop or vacuum that pulls the fuel from the fuel line into the carburettor. The air and fuel mixture then are fed into the cylinders and combusted. Adjusting how much air is allowed into the carburettor is done with the choke and throttle valves, located above and below the Venturi, respectively. With the throttle open, more air and fuel are mixed, producing more power.

The system is simple and easy to maintain but lacks the precision and versatility of fuel-injected systems. And if you’re modifying your bike in any way, say installing high-flow air cleaners and exhausts that change the bike’s stock air/fuel ratio (or the stoichiometric 14.7 parts air to 1 part fuel) by allowing more air in, getting the fuelling spot on is more guesswork considering all the variables. Drawing too much air by modifying the carburettor passageways (or jets, i.e rejecting) leads to a lean fuel mixture and the risk of detonations and destroying the engine, while too little air (and more fuel) means higher consumption, increased emissions or contaminating the engine oil.

Fuel injection removes all of the shortcomings of carburetted engines. High-pressure fuel pumps draw fuel from fuel tanks and lines, which is then sprayed into cylinders at a defined pressure by injectors, based on readings from various engine sensors (Oxygen, Mass Airflow, Throttle Position sensor etc). Sensors monitor various engine parameters, such as oxygen levels, RPMs, and loads. The whole process is controlled by the Engine Control Module (ECM) to ensure that the engine gets the right amount of fuel according to defined ‘maps’ or instructions in the ECM.

Compared to carburettors, injected systems deliver optimal burns, so efficient power regardless of engine and atmospheric temperatures or where and how you’re riding, and prevent common issues like cold starts, or overheating. Another benefit is that all this can be tweaked with a Harley Davidson fuel tuner for even better performance and higher efficiency.

What Do Fuel Tuners Do?

Fuel tuners automatically analyze, tune and adjust air and fuel ratios. Many also perform basic diagnostics by registering injection issues such as sensor malfunctions, failing fuel pumps or debris in the injectors that can lead to misfires, low mileage or overheating due to off fuel mixtures. They can additionally clear error codes.

When connected, the devices read the stock maps for your fuel-injected Harley and with pre-set tuning settings, let the ECM adjust the air and fuel ratios to compensate for any modifications, such as performance air cleaners, aftermarket mufflers or full exhausts. Advanced tuning modules supplied with separate wide-band O2 sensors (with air-fuel ratios between 10:1 and 18:1) are more adept at picking up minute lean or rich mixtures when idling or at higher engine loads, ensuring the longevity of your bike.

Moreover, they easily set optimal air-fuel ratios in heavily modified motorcycles. So, besides tweaking throttle response, fuel use or adjusting powerbands for your riding style, a Harley fuel tuner also helps reduce maintenance needs.

Popular Types

Bluetooth App-based Flash Tuners

These are cheap, extremely popular for basic stage 1 mods, and can rip defined tuning maps off the cloud via an app installed on your phone. Bestsellers here are the Vance and Hines Fuelpak FP4 and the Dynojet PowerVision 4. Both are simple to use, plug into the bike’s diagnostic connector, and let you select from a range of customized parts you’ve added to your Harley. They then automatically tweak the air/fuel ratio to suit your mods by ‘re-flashing’ the ECM with your customized options.

Riders can also choose from several defined maps to suit varied riding conditions or download additional maps from manufacturer websites. The tuning modules are small enough to fit under the seat (or your desired location) and can display other vital data such as average speed, RPMs, journey time and fuel consumption. Both modules have an auto-tune function for quick adjustments and the ability to reset your bike and ECM to factory settings, again with a touch of a button.

‘Piggyback’ Tuners

These are somewhat larger and slightly more costly but have additional functionality, in line with more serious engine mods. They’re permanent (hence piggyback) fixtures and require downloading extensively detailed proprietary maps via manufacturer websites. Common modifications include a wide range of adjustments to the fueling and ignition timing. They also allow for custom tunes according to your preferences. Additional accessories like the wide-band O2 sensors further expand functionality and customisation.

ECM Replacements

The most expensive of the bunch, but with reason. ECM replacements are just that, they replace your Harley’s factory ECM. They too are supplied with wide-band O2 sensors and either download pre-defined manufacturer maps or mimic dyno tuning when riding the bike. The collected data then can be manipulated to get the best performance, optimal fuel use, and adjustability in varied road conditions. Use this for more seriously modified hogs, such as big-bore kits and aftermarket cams to get the performance you expect.

Summing Up

Old-school nostalgia may have played a part in Harley’s late acceptance of electronic fuel injection but with cleaner burns, improved power delivery and consistent performance in hot and cold weather and at different altitudes, Harleys offer effortless riding with none of the hiccups plaguing carburetted engines. When combined with a fuel tuner, Harley-Davidson bikes now get more pep, deliver more fun, reach higher redlines, use less fuel and have the safety of adding any performance modifications without the risk of cooking the engine.