The advancement of smart mobility means that auto parts manufacturers must be more precise, allow for material adaptability, and improve the quality of feedback for electronic components. With more autonomous and connected vehicles appearing, their components should be machined accurately. Many engineers and design teams use automotive prototyping to speed up the work on electromechanical parts related to LIDAR mounts, adaptive lighting enclosures, and embedded modules.

CNC precision machining ensures parts are made with high-quality contours, making it possible to make excellent mechanical prototypes. Thanks to 5-axis milling and multi-material substrate fusion, modern aircraft designs now reach higher standards for functionality, less weight, and heat handling. These developments merge electronics and mechanical systems in modern auto parts manufacturing and encourage a new era of intelligent and combined solutions.

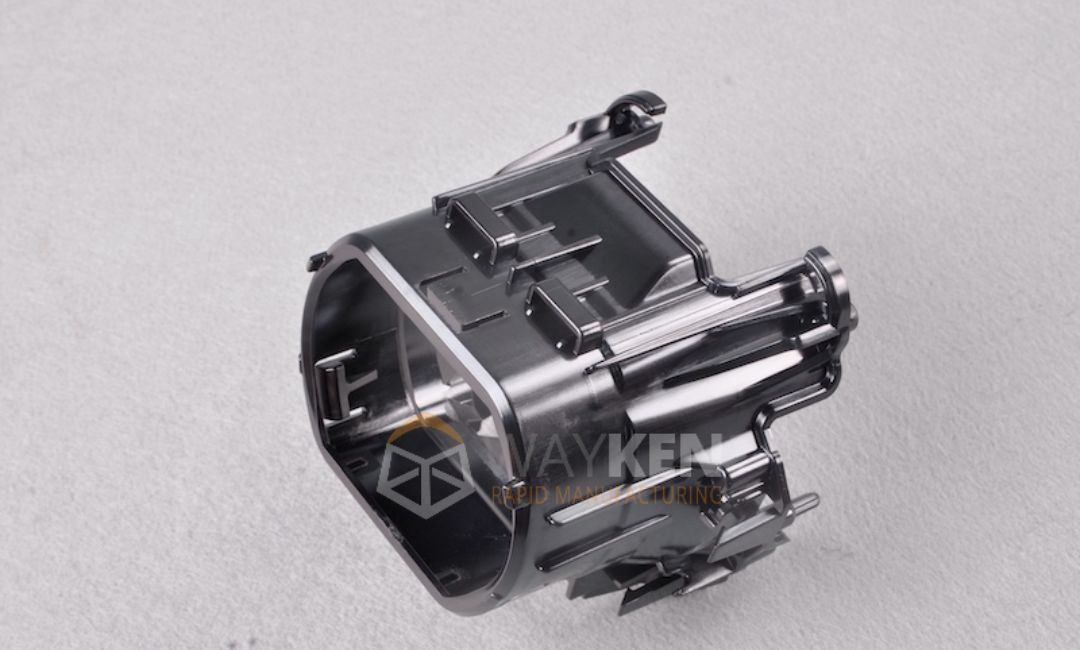

Functional Integration in Sensor Housings and Electronic Modules

Demand to fit sensors and electronic components into limited space and highly stressful areas in cars is expanding at a fast rate. CNC machining helps to make the internal walls and fine parts needed for using MEMS gyroscopes, IMUs, and PCBAs as part of the assembly. The features can be accurately made using a machine without thinning out the material in the part.

To prevent problems such as wire entanglements and overheating, advanced auto part manufacturing uses toolpath simulations in planning wire routes before actual machining. It saves money by decreasing the chances of errors and making sure electrical functions and mechanical parts are properly aligned.

It is very important to use such integration in places near the suspension and engine, as there is not much space, and vibration resistance and shielding against electromagnetic interference should be considered at the same time.

Often, machined aluminum cases in automotive technology support not just the strength of the system, but also help manage heat. In auto parts manufacturing, the 6xxx or 7xxx alloys are typically picked because they are strong and good conductors of heat. Applying the right temper treatments to these alloys enables passive heat removal from a piece without needing to increase its size. Isolation pockets, thermally conductive coatings, and split-shell enclosures are designed using parametric modeling tools.

Next, the designs are made using accurate 3-axis or 5-axis milling. When making prototypes, both grooves and standoffs are given a tolerance of ±10 μm to ensure they make proper thermal contact and to avoid creating stress near those electronic components.

As a result of this high accuracy, the enclosure can handle both heat and mechanical conditions, improving how well and reliably sensor-integrated vehicle equipment operates.

Rapid Iteration through Automotive Prototyping Using CNC-Machined Test Assemblies

The advancements in smart vehicles happen so fast that developers must go through a quick and repeated process of design, testing, and refining. It is possible for engineers to rapidly create experimental parts in the automotive industry because of automotive prototyping.

The effective way to discover if parts are secure and strong is to apply a load to the structure. You can machine small numbers of housings, brackets, and sensor cradles with aerospace-grade aluminum or high-quality polymers such as PEEK and PPS. They are used because they give the required strength, stability, and heat resistance for testing.

CNC machining helps make fine turns to torque-sensitive shafts and optical component holders. Since these improvements focus on fit and function, they do not slow down other project tasks. As a consequence, checking component interfaces for errors is not time-consuming, even when the project moves swiftly.

In addition to checking dimensions, automotive prototyping focuses on fatigue testing, analyzing vehicle vibrations, and ensuring the integration of different systems. Machined prototypes are put in situations that simulate the sounds and jolts of driving and running an engine. When concentricity and the surface finish stay below Ra 0.8 µm, the fidelity and mechanical compatibility of the sensor are affected.

Testing several designs with CNC-machined components makes it possible to compare them using the same test settings. With this strategy, failure analysis is clearer, and it helps to adjust the design by using quantitative measurements.

Material Selection and Aluminum Alloy Performance Under Dynamic Loading

Vehicle parts next to crash systems or suspension ought to be capable of dealing with moving forces and twisting. These places often go through shocks, vibrations, and various kinds of pressure. Requirements for proper functioning are met when suitable materials are used in auto parts manufacturing.

7075-T6 alloys are usually selected since their tensile strength is more than 500 MPa and they can be machine easily. They can be designed for supporting brackets, housings, or mounts that must handle weight.

Engineers use FEA in the CAD stage to discover how the robot will respond to different forces and load. It makes it possible to catch indications of stress from a young age. CNC milling allows the production of accurate pieces, distributing the load properly through all the components. They are used to ensure the parts last longer, because strain testing makes it more likely for broken parts.

Nowadays, advanced manufacturers of auto parts use corrosion modeling to protect electric vehicles from rust in any conditions. By applying either TiCN or DLC coating, the alloys for anodizing or hybrid coats are secured and maintain their safe and appropriate machining level.

By fabricating and post-processing corrosion-resistant parts at any time, automotive prototyping gains efficient access to reliability testing under various corrosive conditions. Major manufacturers also assemble hybrids with aluminum and polymer isolators by adjusting their movements so that these assemblies are well organized. Such accuracy makes the system’s interface reliable under difficult conditions, allowing the smart devices to function longer.

Conclusion

Precision machining underpins the convergence of electronics and mechanics in modern automotive systems. From sensor housings to load-bearing electronic modules, smart design is only as effective as its manufacturable fidelity. Automotive prototyping and auto parts manufacturing will remain at the forefront of intelligent vehicle innovation cycles.

Note: This article is provided by WayKen Rapid Manufacturing and published by our team. All images used in this article are also provided by WayKen. We are not responsible for the accuracy of the information shared.